In the world of scientific research, education, and industrial applications, microscopes are indispensable tools for exploring the microscopic world. However, the variety of tasks they are used for — from biological research to quality control in manufacturing — often requires different specifications and capabilities. For this reason, OEM microscopes are gaining widespread recognition for their ability to offer customization and flexibility, meeting the diverse needs of modern industries and research fields.

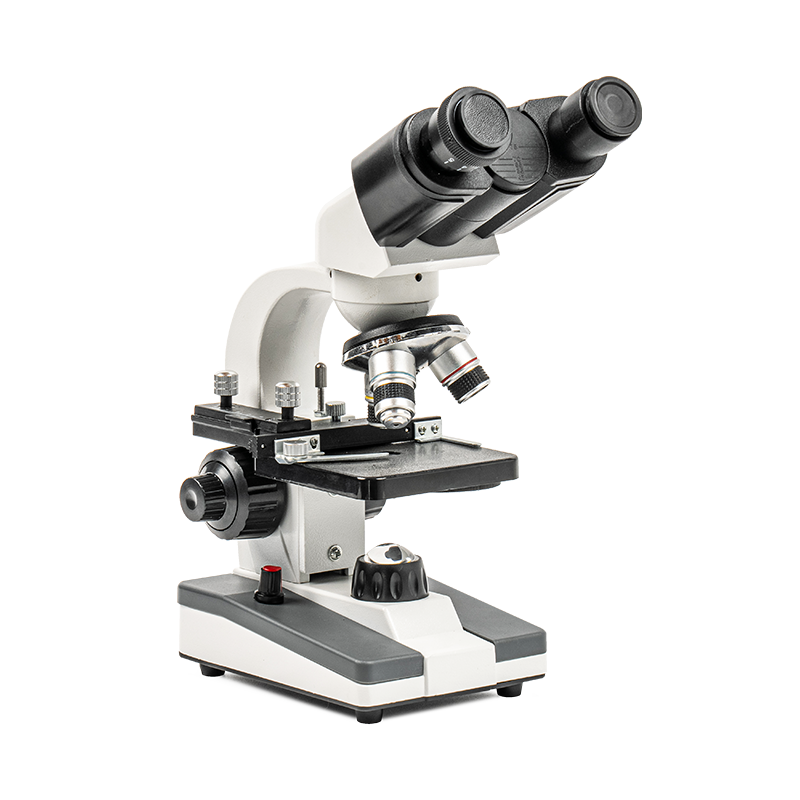

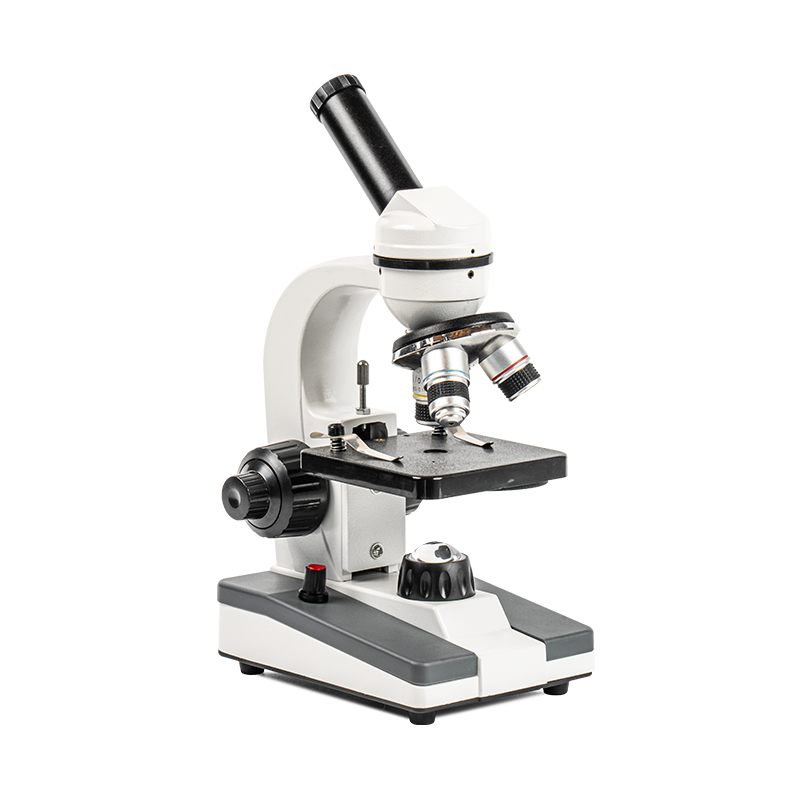

OEM microscopes are essentially microscopes designed and manufactured according to specific customer requirements. Unlike standard models, which are mass-produced for general use, OEM microscopes are tailored to meet the precise demands of the user. These microscopes are used in a wide range of applications, including medical diagnostics, life sciences research, education, material science, and industrial quality control. With their bespoke features and adaptability, OEM microscopes offer a significant advantage over off-the-shelf solutions.

Content

Customization for Research and Development

For researchers and scientists, the ability to customize a microscope to fit specific research needs is invaluable. The standard, off-the-shelf microscope is often not enough for specialized work, especially in fields like cellular biology, nanotechnology, or material science, where the microscope’s performance and configuration need to meet precise requirements.

OEM microscopes offer a high degree of customization in terms of:

Optical configurations: OEM microscopes can be tailored with specific lenses, objectives, and illumination systems, which are essential for obtaining high-quality images in various applications. For example, fluorescence microscopy may require specific filter sets, while super-resolution microscopy needs ultra-high magnification objectives.

Modular design: Many OEM microscopes feature modular components that allow users to easily swap out parts based on their needs. This could include objectives, condensers, and illumination systems, giving users the flexibility to adapt the instrument as research evolves or new applications arise.

Software integration: OEM microscopes can be equipped with customized imaging and analysis software, which is crucial for processing and analyzing data from specialized experiments. Whether it’s for 3D reconstruction, particle analysis, or time-lapse imaging, the software can be designed to integrate seamlessly with the specific needs of the laboratory.

This customization makes OEM microscopes an ideal choice for research institutions and labs, where scientific exploration often requires specialized, adaptable equipment that can handle cutting-edge research techniques.

Enhanced Imaging Capabilities

Imaging quality is a crucial aspect of any microscope, and OEM solutions provide flexibility in enhancing imaging capabilities based on user requirements. Whether it's for high-resolution imaging, high-speed capture, or deep-tissue imaging, OEM microscopes can be optimized to deliver exceptional performance.

Key aspects of enhanced imaging in OEM microscopes include:

Advanced illumination systems: OEM microscopes can be equipped with various illumination techniques such as brightfield, darkfield, phase contrast, differential interference contrast (DIC), and fluorescence. Each of these techniques offers different advantages for observing specific samples, making it easier to extract detailed information from the specimen being studied.

High-Resolution Imaging: Some OEM microscopes are specifically designed for high-resolution imaging, which is crucial in areas like nanotechnology or materials science. Custom optics and camera integration can enable a level of detail that standard microscopes may not provide. For instance, custom objectives with extremely high numerical apertures (NA) can deliver greater resolving power, which is vital for observing structures at the nanoscale.

3D Imaging and Live Imaging: OEM microscopes can also be customized for advanced imaging techniques such as confocal microscopy, which allows researchers to observe 3D structures within samples. For live cell imaging, features like time-lapse imaging and temperature-controlled stages can be integrated into OEM microscopes, allowing for the real-time observation of dynamic biological processes.

These custom imaging features enable researchers to perform highly specialized tasks, ensuring that the equipment can meet the exact needs of a particular project or experiment.

Customization in Education and Training

OEM microscopes also offer significant advantages for educational and training purposes. Schools, universities, and medical training institutions often require microscopes that provide educational value while also fitting within a budget. However, educational microscopes have distinct needs in terms of ease of use, durability, and adaptability to different teaching styles.

OEM microscopes for educational purposes can be designed with:

Ergonomic features: Adjustable focus mechanisms, comfortable eyepieces, and user-friendly interfaces can be integrated into OEM microscopes, making them easier to use for students and educators alike.

Durability and Longevity: Educational microscopes need to withstand frequent use and handling, so manufacturers can produce OEM models with robust frames, high-quality materials, and reinforced components to ensure durability over time.

Modular configurations: Similar to research microscopes, educational microscopes can be customized with various configurations, from basic models for elementary education to more advanced versions for higher education and university-level research. This modularity ensures that the equipment can evolve as educational needs change over time.

Incorporation of digital features: Many educational microscopes are now incorporating digital technology, such as integrated cameras, screens for live image viewing, and software for image analysis. OEM microscopes can be customized with these features, providing students with hands-on experience in digital microscopy and data analysis.

These customizations help ensure that the microscopes used in educational institutions are not only durable and cost-effective but also provide the flexibility needed for diverse teaching scenarios.

Industrial Applications and Quality Control

In industrial applications, OEM microscopes are often required for tasks like quality control, materials inspection, and precision measurements. Industries such as semiconductor manufacturing, metallurgy, automotive, and pharmaceuticals rely on high-performance microscopes to ensure product quality and meet stringent regulatory standards. The ability to customize microscopes for specific industrial uses is crucial to enhancing inspection processes and maintaining quality assurance.

Custom features in industrial OEM microscopes include:

High-precision measurements: For industries requiring precise measurement of microstructures, OEM microscopes can be equipped with customized measuring systems, such as micrometers or software that allows for precise analysis of surface textures, dimensions, and alignment.

Environmental control: For applications like materials science, where temperature or humidity control is critical, OEM microscopes can be integrated with environmental chambers or stages that provide controlled conditions for sample observation. This customization is vital for examining materials under specific conditions, such as high temperatures or pressures.

Automated systems: Many industrial microscopes need to incorporate automated functions for high-throughput analysis. OEM manufacturers can design microscopes that are capable of automated sample scanning, focus adjustment, and even image analysis, making them ideal for applications that require rapid and consistent results.

Robustness and Adaptability: Industrial settings often require microscopes that can handle rough conditions, such as exposure to dust, chemicals, or extreme temperatures. OEM microscopes can be built with rugged, industrial-grade materials to ensure reliability even in harsh environments.

The flexibility of OEM microscopes allows industrial sectors to meet demanding quality control standards while also improving operational efficiency.

Integration of Advanced Technologies

As scientific and industrial fields continue to evolve, the need for cutting-edge technologies in microscopy becomes more pressing. OEM microscopes are often at the forefront of incorporating emerging technologies to enhance functionality and expand their capabilities. These technologies include:

Artificial Intelligence (AI) and Machine Learning: OEM microscopes can integrate AI-driven image analysis algorithms that can automatically detect patterns, classify cells, or identify defects. This integration helps speed up the process of data analysis, reducing the need for manual inspection and allowing for more accurate results.

Robotics and Automation: In laboratories and industrial facilities that require high-throughput analysis, OEM microscopes can be customized with robotic arms for automatic sample loading, positioning, and image capture. This automation streamlines workflows, improving overall efficiency and reducing human error.

Nanotechnology: As nanotechnology continues to advance, OEM microscopes can be customized with specialized features for imaging and manipulating nanoscale structures. These features include ultra-high magnification, advanced electron microscopy integration, and customized sample holders for nano-manipulation.

By integrating these advanced technologies, OEM microscopes provide users with state-of-the-art tools for research, quality control, and development.

Cost-Effectiveness and Scalability

One of the main reasons OEM microscopes are so appealing to a wide range of sectors is their cost-effectiveness. Although OEM microscopes can be more expensive upfront than off-the-shelf models, they are often a more cost-effective solution in the long run. Customizing microscopes for specific applications reduces the need for additional equipment or modifications down the road. Additionally, many OEM manufacturers offer scalable solutions that allow for easy upgrades as research or industry needs evolve.

For example, a laboratory may start with a basic OEM microscope and later upgrade it with more advanced optics, additional software capabilities, or imaging features as research progresses. Similarly, an industrial facility may start with a standard microscope but later incorporate more specialized functions for specific inspection tasks.

This scalability ensures that organizations can invest in equipment that will grow with their needs, without having to replace entire systems every few years.

English

English Español

Español عربى

عربى 中文简体

中文简体