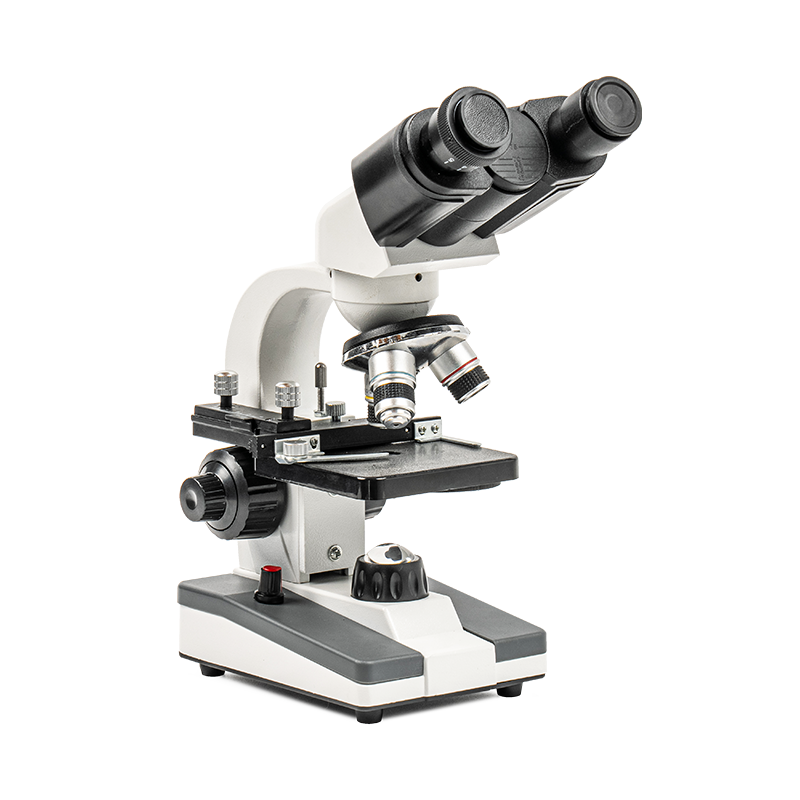

Against the backdrop of accelerated global technological evolution, optical microscopy equipment that once seemed "traditional and stable" is being completely reconstructed. Compound Binocular Microscope, as a basic tool in scientific research, education, medical care and other fields, is regarded as the "mainstay" of microscopic instruments due to its wide range of application scenarios and deep technical accumulation. Today, driven by the intersection of many cutting-edge technologies such as artificial intelligence, automatic control, and digital imaging, binocular compound microscopes are ushering in a true "rebirth". This "rebirth" is not only an enhancement of product functions, but also a profound change from thinking mode to industry application mode - technological leap is becoming the core driving force for the innovation of the entire industry.

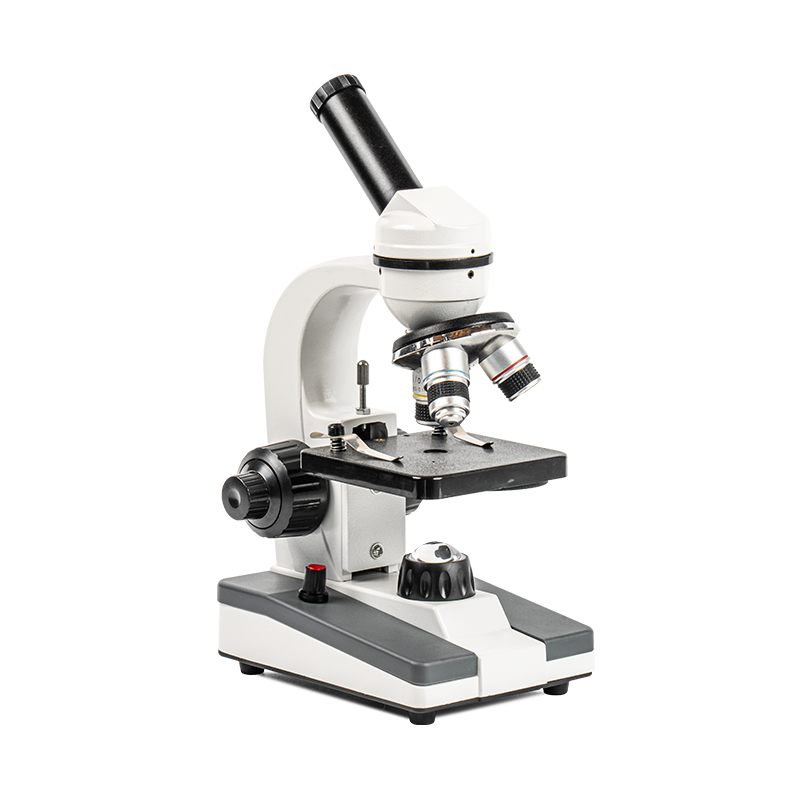

The traditional impression of binocular compound microscopes is often manual operation, simple structure, and basic application. However, at present, a new generation of technologies represented by AI vision, digital image processing, and intelligent control systems are accelerating their integration into this equipment, and dramatic changes are taking place from the underlying structure to the functional logic.

Thanks to the improvement of optical manufacturing technology, modern binocular compound microscopes generally use infinity correction systems, apochromatic lenses, high-transmittance coatings and LED cold light sources, which greatly improve the image quality and color reproduction ability.

Especially in high-magnification observations, traditional equipment often affects the analysis results due to image blur and edge distortion. Through new materials and precision design, the latest model of microscopes can still maintain sharp images at more than 1000 times, effectively meeting the needs of high-end applications such as scientific research and medicine. The biggest sign of technological leap is the fundamental change in operation mode. Relying on stepper motors, multi-axis electric control platforms and AI focusing algorithms, the new binocular compound microscope can achieve automatic focusing, field of view switching, objective lens rotation and scanning control.

This not only greatly reduces the user's operating burden, but also significantly improves the degree of experimental standardization. For example, in biological slice observation, automatic identification of sample areas and edge alignment can greatly reduce human errors; in industrial inspection, automatic inspection of batch samples can be achieved by setting programs.

The leap of technology ultimately rests on the expansion of applications. The binocular compound microscope is "reborn" not only because of its upgraded functions, but also because these functions precisely meet the urgent needs of many fields at present.

In the fields of electronic manufacturing, material research, cosmetics testing, etc., the fine observation of microstructures is increasingly dependent on high-end microscopic equipment. Intelligent microscopes equipped with functions such as **automatic recording, image comparison, and data export** are becoming the "standard configuration" of corporate quality control departments and R&D teams. It can be linked with experimental software and database platforms to achieve long-term accumulation and traceability of microscopic data, effectively improving experimental reproducibility and R&D efficiency.

In the past, the high-end market for optical microscopes was mainly monopolized by foreign brands. But now, driven by technological leaps, Chinese companies are gradually breaking this pattern. From optical lenses, image sensors, to control systems and AI algorithms, more and more domestic manufacturers no longer rely on foreign purchases, but have created a complete independent industrial chain. This not only brings cost advantages, but also enables products to be better localized to adapt to the needs of education, medical and industrial users. Compared with the characteristics of traditional foreign-funded products that focus on hardware and light on software, domestic brands pay more attention to the coordination of software and hardware and the optimization of intelligent experience. Through collaboration with educational technology companies and AI algorithm companies, domestic microscopes have gradually built an intelligent ecosystem of "hardware as platform" to adapt to the rapid development trend of digital teaching and smart medical care.

English

English Español

Español عربى

عربى 中文简体

中文简体